Flashlamp Design Overview

A flashlamp is a gas discharge light source designed to produce pulsed radiation. It is capable of providing much higher peak intensity than are available with continuous light sources. The flashlamps range of performance is extremely broad with an electrical input energy range from 10-3 to 105 joules per pulse, pulse lengths from 10 -3 to 105 microseconds and pulse repetition rates from a single shot to 5 x 104 Hz.

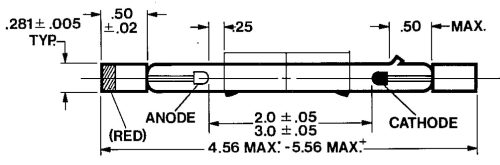

Typical Laser Flashlamp

Modern solid-state lasers rely on linear Xenon flashlamps between 2.5cm and 15cm long with bores from 1 to 10 mm in diameter. These flashlamps are filled with Xenon gas and produce high energy white light pulses. Many flashlamps produce a substantial amount of ultraviolet light that can be best utilized with a UV-transmitting glass envelope, for example made of quartz (fused silica). In other cases, UV generation is unwanted and can be suppressed by using envelopes of doped glass, exhibiting increased UV absorption.

To best utilize the light output of Xenon flashlamps to excite laser rods, containment of the light is essential. Laser pump chambers are used to house the lamp and laser rod in a highly reflective cavity that concentrates as much light energy on the laser rod as possible. High efficiency packed powder (typically barium sulfite) cavities are preferred for various laser rods including Nd:YAG, Er:YAG, Alexandrite, CTH:YAG and Ruby.

Proper cooling of flashlamps is essential for long life and reliable operation. Over the years cooling requirements for flashlamps have become well defined. For average powers below 15W/cm2 convection cooling is permissible. Between 15W/cm2 and 30 W/cm2 forced air cooling is required. Above 30W/cm2 liquid cooling is mandatory. These power levels assume operation in a laser pump cavity where a substantial amount of the radiation is reflected back into the lamp. Deionized water is typically use to cool flashlamps and laser pump chambers due to its nonconductive properties. Conductive water can short out the lamp starting pulse causing unreliable firing. In addition deionized water reduces corrosion problems with electrical connections in the coolant. Water resistivity greater than 300kΩ is a required minimum but many laser systems are configured for water resistivity of up to 1MegΩ.

The electrical energy for pulsing flashlamps requires specially designed power supplies and high voltage networks that can deliver high current, short pulses to the lamp. A typical system consist of a high voltage current source or capacitor charging power supply, a capacitor or bank of capacitors to store large amounts of energy and a high voltage switch to deliver the pulses to the flashlamp. To start and maintain the arc in the lamp, external triggering is widely used in combination with a low current “simmer power supply.”

Early solid-state lasers utilized traditional RLC networks to generate high peak current to the lamp. These pulse forming networks (PFNs) were limited to a very narrow pulse width and were very inefficient. Today most lasers use partial discharge configurations that allow for a wide range of pulse widths and repetition rates. This versatility is very desirable in medical applications that require the laser to be used on a wide variety of procedures.

For more information on any of the product mentioned above contact: sales@newsourcetechnology.com